Energy Savers’ Circle

Hydro-Québec’s Energy Savers’ Circle brings together large-power customers recognized for their exceptional energy efficiency leadership and performances.

New member of distinction

Rio Tinto Aluminium

Distinction

A member of the Energy Savers’ Circle since 2006 and an Elite member since 2011, Rio Tinto Aluminium rose to Distinction status thanks to efficiency measures that have led to remarkable annual electricity savings of 343 GWh, confirming its status an a energy efficiency leader.

To achieve these savings, Rio Tinto Aluminium led a number of energy efficiency projects and initiatives, including:

- electricity consumption analyses to determine opportunities to increase its efficiency

- the application of the measures identified as part of these analyses

All members

As part of our energy efficiency programs, members of the Energy Savers' Circle carried out energy efficiency projects that resulted in significant energy savings. In order to achieve their goal, they implemented energy efficiency policies and nominated in-house energy efficiency representatives.

2nd Canadian Division Support Base Valcartier

Hydro-Québec is very pleased to welcome the 2nd Canadian Division Support Base Valcartier into the Energy Savers’ Circle. Thanks to its energy efficiency initiatives, the Support Group reduced its annual electricity consumption by 7%.

To achieve these results, the Group implemented a series of energy efficiency measures: including:

- enhanced lighting by installing a central control unit and induction fixtures

- the addition of variable speed drives (VSDs) to its fans

- the replacement of its air-conditioning system with more efficient units

- the upgrade of its regulation systems

- the construction fo a LEED building equipped with features including a geothermal heat pump, a solar wall and efficient lighting

Ab Mauri (Canada) – Lasalle

Thanks to its keen interest in new technologies, Fleischmann's Yeast cut its consumption by 17%.

- Improved the energy efficiency of blowers used during the yeast fermentation process.

Agnico-Eagle Mines - Cadillac

Agnico–Eagle Mines achieved a 6% reduction in its power use.

A complete energy analysis of its LaRonde mining operations in Abitibi enabled Agnico-Eagle Mines to launch several new energy efficiency initiatives.

Air Liquide

Hydro-Québec is pleased to welcome Air Liquide, a world leader in gases, technologies and services for industry and health to the Energy Savers’ Circle. Thanks to its energy efficiency initiatives, Air Liquide reduced its annual electricity consumption by 6%.

To achieve these savings, Air Liquide implemented a series of energy efficiency measures, including:

- the enhancement of its nitrogen charge process

- the upgrading of its lighting system by replacing its standard high-bay fixtures with LED lighting

Akzonobel, Valleyfield Plant

Between 2006 and 2011, AkzoNobel reduced the annual electricity consumption of its Valleyfield plant by 5% thanks to over 20 energy efficiency projects, including a large-scale initiative to optimize the energy efficiency of its electrolysis system.

Alcoa – Baie-Comeau aluminum smelter Distinction

Alcoa’s Baie-Comeau aluminum smelter, which joined the Energy Savers’ Circle in 2011 and has been an Elite member since 2012, rose to Distinction status in 2014 thanks to efficiency measures that led to remarkable annual electricity savings of 329 GWh.

To achieve these savings, Alcoa’s Baie-Comeau smelter carried out six energy saving projects and carried out a number of initiatives, including:

- Implementing a number of measures identified by energy analyses

- Improving its electrolysis process

- Automating its compressed-air system in order to generate savings

Alcoa – Deschambault aluminium smelter Distinction

Alcoa’s Deschambault aluminum smelter, which joined the Energy Savers’ Circle in 2008 and has been an Elite member since 2012, rose to Distinction status in 2014 thanks to efficiency measures that have led to remarkable annual electricity savings of 338 GWh.

To achieve these savings, Alcoa’s Deschambault smelter carried out 10 energy efficiency projects, including:

- Improving its production processes

- Performing energy audits to target energy efficiency strategies

- Optimizing production and the use of compressed air

Aluminerie Alouette Inc. – Sept-Îles

Aluminerie Alouette reduced its power consumption by 140 GWh.

Following a complete energy analysis of its facilities, the Sept-Îles aluminum smelter optimized the heat balance of its electrolytic cells, considerably reducing the amount of energy lost during the process.

Aluminerie de Bécancour inc. Distinction

Aluminerie de Bécancour inc., which joined the Energy Savers’ Circle in 2008 and has been an Elite member since 2011, rose to Distinction status in 2014 thanks to efficiency measures that have led to remarkable annual electricity savings of 317 GWh.

To achieve these savings, Aluminerie de Bécancour carried out seven energy efficiency projects, including:

- Implementing a number of measures identified by energy analyses

- Improving its production processes

ArcelorMittal Tubular Products – Montréal

By installing energy-efficient compressors, ArcelorMittal Tubular Products Montréal was able to reduce the electricity consumption of its Montréal plant by 7%.

The company has manufactured steel tubing for close to 100 years. In Québec, ArcelorMittal employs over 2,000 people in five locations in the greater Montréal area. It is part of the ArcelorMittal Group, a world leader in the steel industry, which employs 310,000 workers in over 60 countries.

ArcelorMittal – Longueuil bar mill

Hydro-Québec is very pleased to welcome ArcelorMittal’s Longueuil bar mill, a leader in steel, to the Energy Savers’ Circle. Thanks to its energy efficiency measures, ArcelorMittal reduced the annual electricity consumption of its Longueuil bar mill by 6%.

To achieve these results, the company implemented a series of measures, including:

- a major overhaul of its indoor lighting system

Axiall Canada - Beauharnois

Axiall Canada's Beauharnois plant improved its electrolytic process, making it more effective and less energy-consuming. This initiative helped the company reduce its electricity consumption by 5%.

Balcan Plastics - Montréal

Balcan Plastics generated electricity savings of 16% in two of its plants.

- Modernization of many fusion machines

Banque Nationale and Gestion immobilière Dream Office

Hydro-Québec is very pleased to welcome Banque Nationale et Gestion immobilière Dream Office into the Energy Savers’ Circle. Thanks to their energy efficiency initiatives, the corporations reduced their annual electricity consumption by 8%.

To achieve these results, Banque Nationale et Gestion immobilière Dream Office implemented a series of energy efficiency measures, including::

- variable-speed drives (VSDs) on the ventilation systems and heating and cooling pumps

- replacing cooling units with more efficient models

- CO2 sensors to regulate fresh air and the adjustment of the exhaust air flow rate

- an upgraded lighting system

Barrette-Chapais

The Barrette-Chapais sawmill in Chapais reduced its electricity consumption by almost 6%.

The company installed higher-performance equipment with variable-frequency drives including a hog, a ventilation fan, a variable-rate compressor and hydraulic system components.

Barry Callebaut

Hydro-Québec is pleased to welcome Barry Callebaut to the Energy Savers’ Circle, thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 12%.

To achieve these savings, the company carried out five energy efficiency projects and implemented a series of measures, including:

- Automating agitators and pumps

- Upgrading its compressed-air system

Bombardier Aerospace – Dorval

The Dorval plant achieved energy savings of nearly 6% by:

- Replacing over 5,500 compact fluorescent bulbs with more energy efficient ones.

- Overhauling its compressed-air system.

Bombardier Aerospace – Saint-Laurent

The Saint-Laurent plant has distinguished itself by reducing its electricity consumption by 14%.

Seven projects were implemented, resulting in the optimization of compressed-air and lighting systems and Cincinnati milling machines.

Bombardier Transportation Canada – La Pocatière

Bombardier Transportation's plant in La Pocatière improved its compressed air system and reduced its power consumption by 12%.

- Installation of more energy efficient compressors

Bridgestone Canada Inc. – Joliette Plant

Hydro-Québec would like to highlight Bridgestone Canada’s energy efficiency initiatives in its Joliette plant and welcome it to the Energy Savers’ Circle. The plant has managed to reduce its annual electricity consumption by 7%.

To achieve these savings, it carried out eight energy efficiency projects and implemented a series of measures, including:

- Undertaking a large-scale replacement of one type of lighting by a more efficient model

- Installing variable-speed drives on pumps

Building Products of Canada Corp. - Pont-Rouge

Building Products of Canada Corp. reduced the annual energy consumption of its Pont-Rouge plant by 5% by implementing the following measures:

- Optimization of wood pulp refining process.

- Installation of automatic control systems and new measuring instruments.

- Replacement of three compressors with one variable compressor

CAE

Hydro-Québec is pleased to welcome CAE to the Energy Savers’ Circle. A global leader in modeling, simulation and training for civil and defense aviation committed to energy efficiency, the company has managed to reduce its annual electricity consumption by 6%.

To achieve these savings, the company carried out five energy efficiency projects and implemented a series of measures, including:

- Replacing equipment and installing controls to upgrade lighting

- Adding controls to recover heat generated in the electrical rooms in winter

Canada Pipe Company - Bibby-Ste-Croix - Ste-Croix

Bibby-Ste-Croix achieved electricity savings of 10% by optimizing its compressed air system.

- Seven inefficient compressors were replaced by three new compressors designed to regulate system pressure according to the plant's requirements.

- Dessicant air dryers were replaced by a refrigerant air dryer, which uses less compressed air in the air-drying process.

- In addition, fans were used instead of compressed air to supply combustion air to equipment that bakes moulds used to manufacture cast-iron pipes.

Canada Post- Saint-Laurent

Canada Post reduced the electricity consumption of its mail processing plant in Saint-Laurent by nearly 7%.

The plant enhanced its lighting systems, making them more energy efficient.

Cargill Ltd – Baie-Comeau

The Baie-Comeau facility of Cargill, a major international food merchandiser and processor, has joined the Energy Savers’ Circle thanks to energy efficiency measures that have led to significant annual energy savings of 9%.

To achieve these savings, the company carried out two projects and implemented a series of measures, including:

- Replacing lighting equipment

- Replacing a compressor with a more efficient model

Cascades Boxboard Group – Jonquière

Hydro-Québec welcomes Cascades Boxboard Group’s Jonquière mill to the Energy Savers’ Circle thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 12%.

To achieve these savings, the mill carried out seven energy efficiency projects and implemented a series of measures, including:

- Installing variable-speed drives

- Upgrading lighting

- Installing a compressed-air system and high-efficiency dryers.

Cascades Canada ULC – Kingsey Falls

Hydro-Québec is pleased to announce that Cascades Canada’s Kingsey Falls facility has joined the Energy Savers’ Circle thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 5%.

To achieve these savings, the company carried out more than 30 projects and implemented a series of measures at six different plants: Cascades Tissue Group – Kingsey Falls; Norampac – Kingsey Falls; Plastiques Cascades; Cascades Forma-Pak; Cascades Paper – Kingsey Falls; Cascades Conversion – Kingsey Falls, including:

- Installing LED lighting on a large scale at the conversion plant

- Replacing pumps and compressors with more efficient models

- Upgrading compressed-air systems

Cascades Lupel - Cap-de-la-Madeleine

Cascades Lupel lowered its electricity consumption by 9% by:

- Replacing outdated equipment with higher-performance machinery (pulper agitator, main compressor and boiler feed pump).

- Modernizing its lighting system, which now includes centralized controls

Cascades Tissue Group – Candiac

Hydro-Québec welcomes Cascades Tissue Group - Candiac to the Energy Savers’ Circle thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 5%.

To achieve those savings, the mill carried out six projects, including:

- Upgrading the lighting system

- Replacing a compressor and dryer with more efficient models

- Modifying the sludge treatment and purification system

Casino du Lac-Leamy - Gatineau

The Casino du Lac-Leamy reduced its annual electricity consumption by 10%.

The Casino du Lac-Leamy is among the Outaouais’ must-see attractions. After assessing the systems and equipment, the Casino du Lac-Leamy implemented a series of measures, including projects to:

- optimize the ventilation systems at the Lac-Leamy Hilton Hotel and the Casino du Lac-Leamy

- upgrade the heating, air-conditioning and lighting systems at the Lac-Leamy Hilton Hotel

Chantiers de Chibougamau

Hydro-Québec is very pleased to welcome Chantiers Chibougamau, which manufactures and markets highly competitive forest products, into the Energy Savers’ Circle. Thanks to its energy efficiency initiatives, Chantiers Chibougamau has reduced its annual electricity consumption by 18%.

To achieve these results, Chantiers Chibougamau implemented a series of energy efficiency measures, including:

- an analysis of its energy consumption

- the optimization of its:

- debarkers by enhancing their efficiency

- indoor and outdoor lighting systems

- compressors by adding variable-speed uni drives (VSDs).

CHU de Québec Elite

Hydro-Québec would like to draw attention to the CHU de Québec’s remarkable efforts and success in energy efficiency. Thanks to initiatives that have led to record annual energy savings of 21%, it has joined as an Elite member.

To achieve these savings, the hospital carried out seven energy efficiency projects and implemented a series of measures, including:

- Carrying out a heat recovery project

- Installing efficient lighting

- Optimizing the ventilation system

Ciment Québec - Saint-Basile

Ciment Québec in Saint-Basile cut its energy consumption by over 5%.

- The company installed bucket elevators - a more efficient system to transport raw meal (cement powder).

- Replaced a fan and compressors with more energy-efficient equipment.

Cominar - Sainte-Foy

By upgrading its cooling system, Cominar slashed its electricity consumption by 15%.

- Two new coolers that use heat recovery were installed, along with a new glycol tower for free cooling.

- Ten variable-speed drives were added to the pumping systems.

- A portion of the steady-volume air distribution system was converted to a variable-volume system.

Complexe Desjardins - Montréal

The Complexe Desjardins stands out and reduces its power consumption by 6%.

Place Desjardins opted for more energy-efficient equipment.

- Replaced the lighting system

- Installed highly energy-efficient coolers in the water cooling system

École de technologie supérieure (ÉTS)

Hydro-Québec is pleased to announce that the École de technologie supérieure has joined the Energy Savers’ Circle. The school has lowered its annual electricity consumption throughout its campus by at least 9%.

To achieve these savings, the school implemented several energy efficiency initiatives in various construction and renovation projects, including:

- opting for integrated equipment management thanks to a centralized control system;

- adding new heat recovery equipment and technologies;

- adopting an ongoing optimization practice for electromechanical systems;

- building energy-efficient buildings that use electricity as their main source of energy.

Energizer

Thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 8%, Energizer, a leader in its field, has joined the Energy Savers’ Circle.

To achieve these savings, the company carried out six energy efficiency projects and implemented a series of measures, including:

- Refurbishing lighting systems

- Carrying out a major project to use recovered heat for heating water

- Optimizing ventilation use.

ERCO Worldwide, A Division of Superior Plus- Gatineau Élite

A member of the Energy Savers’ Circle since 2009, ERCO Worldwide set itself apart by reducing its annual electricity consumption by 6%.

To do so, ERCO Worldwide implemented some 50 energy efficiency projects, making energy management a priority at every level. Thanks to these significant efforts, ERCO Worldwide is now recognized as an energy efficiency ambassador in its sector.

Exceldor - Saint-Damase

Exceldor reduced the electricity consumption of its Saint-Damase plant by almost 10% by :

- Reducing heat distribution system losses by optimizing its electric boilers.

- Recovering wastewater by installing heat pumps and exchangers to preheat production water.

General Dynamics Ordnance And Tactical Systems - Canada – Le Gardeur

The Valleyfield plant reduced its annual electricity consumption by 6% by optimizing its central compressed air system and modifying the ventilation systems in two workshops. These changes curbed the company's energy consumption and lessened workers' exposure to chemical vapors.

Goldcorp - Éléonore

Hydro-Québec is very pleased to welcome the Goldcorp – Éléonore gold mine to its Energy Savers’ Circle. Thanks to its energy efficiency measures, Goldcorp - Éléonore as reduced its annual electricity consumption by 11%.

To achieve these savings, Goldcorp - Éléonore implemented a series of energy efficiency measures, including:

- two electricity consumption analyses

- the installation of a double-stage compressor system with variable-frequency drives (VFDs)

Groupe Hypertec

Hydro-Québec is very pleased to welcome the Groupe Hypertec, a global IT solutions provider, to its Energy Savers’ Circle. Thanks to its energy efficiency initiatives, the Groupe Hypertec reduced its annual electricity consumption by 8%.

To achieve these results, the Groupe Hypertec implemented a series of energy efficiency measures, including:

- the installation of efficient equipment:

- efficient lighting and occupancy sensors

- CO2 sensors to control fresh air supply

- Variable-speed drives (VSDs) to regulate ventilator fans

- SRCs and Triac controllers to regulate the power in the electric coils and baseboard heaters

- VSDs to regulate ice-water loop pump motors

Hôpital général juif

Hydro-Québec is very pleased to welcome Hôpital Général Juif to the Energy Savers’ Circle. Thanks to its energy efficiency measures, the hospital reduced its annual electricity consumption by 5%.

To achieve these results, Hôpital Général Juif implemented a series of energy efficiency measures, including:

- a new heat recovery system and high-efficiency air-conditioning units

- the installation of a variable speed compressor

- the addition of variable-speed drives (VSDs) to ventilator fans and heating pumps

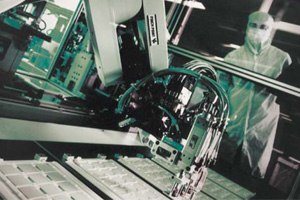

IBM Canada LTD – Bromont plant Distinction

IBM Canada Ltd.’s Bromont plant, which joined the Energy Savers’ Circle in 2006 and has been an Elite member since 2011, rose to Distinction status thanks to efficiency measures that have led to remarkable annual electricity savings of 27%.

To achieve these savings, IBM Canada’s Bromont plant carried out more than 40 energy efficiency projects and implemented a number of initiatives, including:

- Optimizing lighting and lighting control systems

- Improving pumping of chilled water

- Recovering heat from compressed-air systems

Infasco

For its energy efficiency enhancement achievements, Hydro-Québec welcomes Infasco, the largest North American manufacturer and distributor of fasteners and fastener products, to the Energy Savers’ Circle. The company has managed to reduce its annual electricity consumption by 10%.

To achieve these savings, it carried out four energy efficiency projects and implemented a series of measures, including:

- Replacing two compressors

- Installing a variable-speed compressor

- Undertaking a major replacement of the indoor lighting system

IPL Inc.

Thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 7%, IPL, a major manufacturer of injection-molded plastic products, has joined the Energy Savers’ Circle.

To achieve these savings, the company carried out five energy efficiency projects and implemented a series of measures, including:

- Optimizing the cooling circuit of hydraulic units on injection-molding machines

- Undertaking a major replacement of lighting equipment

Ivanhoé Cambridge - Centre Laurier - Québec

Cooling and lighting system optimization; heating, ventilation and air-conditioning system optimization and automation. These initiatives led to energy savings of 5%.

Ivanhoé Cambridge - Centre Rockland - Montréal

Implementation of a new centralized energy management system to optimize the operating schedules of the stores' rooftop units and parking lot lighting. This initiative led to energy savings of 12%.

Ivanhoé Cambridge – The Montréal Eaton Centre

Thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 10%, Ivanhoe Cambridge’s Eaton Centre in Montréal has joined the Energy Savers’ Circle.

To achieve these savings, the company carried out three energy efficiency projects and implemented a series of measures, including:

- Installing variable-speed drives on fans

- Replacing a chiller with a more efficient model

- Carrying out a project to recover heat from chillers for use in heating the building.

Kruger - Place Turcot - Montréal

Since 2005, Kruger has undertaken 10 energy efficiency projects, leading to a 5% reduction in energy consumption at the Place Turcot paperboard mill. These measures include:

- The installation of a very-high-efficiency motor

- The replacement of a refiner by a high-performance model

- The replacement of two vacuum pumps by a single, more efficient pump

- The installation of efficient rotors

Kruger Products – Crabtree Mill

Hydro-Québec is pleased to welcome Kruger Products’ Crabtree mill to the Energy Savers’ Circle thanks to its energy efficiency initiatives that have lowered its annual electricity consumption by 5%.

To achieve these savings, the paper mill carried out six energy efficiency projects and implemented a series of measures, including:

- Replacing indoor lighting system

- Modifying compressed-air systems.

Labatt Breweries – Lasalle

Labatt Breweries – LaSalle reduced its annual electricity consumption by 10%.

- The company enhanced its ammonia refrigeration system and intake and exhaust fans following an energy consumption analysis and installed new lighting and motion sensor systems.

Lantic Sugar - Montréal

Lantic Sugar reduced its annual electricity consumption by 6% by making considerable efforts to develop an energy efficiency action plan. The corporation also optimized the water pumping system used in the sugar manufacturing process by:

- modulating pump flows

- replacing pumps with high-performance models.

Linde Canada Limited - Magog

Linde Canada Limited reduced the electricity consumption of its Magog plant by 5%. These energy savings were made possible by replacing the hydrogen liquefier turbines with more efficient models, decreasing turbine compression, modifying the process and enhancing the cooling tower.

McGill University

McGill University has joined the Energy Savers’ Circle thanks to many initiatives that have reduced its annual electricity consumption by 8%.

To achieve these savings, the university carried out more than 20 energy efficiency projects and implemented a series of measures, including:

- Updating mechanical systems and labs in the Otto Maass building

- Installing fan-coil heaters for labs

- Optimizing building ventilation systems.

Mcgill University Health Centre - Royal Victoria Hospital - Montréal

The Royal Victoria Hospital joined the Energy Savers’ Circle after reducing its annual electricity consumption by 6% through a series of initiatives, including projects to:

- upgrade the lighting system and booster pumps (for water supply)

- decrease kitchen equipment airflow

- reconfigure the air conditioning system and optimize ventilation system programming

Mines Agnico-Eagle - Cadillac

Mines Agnico-Eagle a réduit sa consommation de 6 %.

L'entreprise a procédé à une analyse énergétique complète des installations de la mine LaRonde, en Abitibi. Une analyse qui a donné lieu à plusieurs projets d'efficacité énergétique.

Molson Coors Canada - Montréal Elite

Molson Coors Canada, one of the first members of the Energy Savers’ Circle (admitted in 2005), earned Élite member status by reducing its annual electricity consumption by 22%.

The corporation adopted several best practices in energy management and is actively working to develop and implement a range of energy efficiency projects.

Norampac – Cabano

Hydro-Québec is pleased to welcome Norampac - Cabano to the Energy Savers’ Circle. By focusing on energy efficiency, the mill has managed to reduce its annual electricity consumption by 5%.

To achieve these savings, it carried out more than 20 energy efficiency projects and implemented a series of measures, including:

- Installing variable-speed drives on pumps, fans and other equipment

- Replacing refiners with high-efficiency models

- Installing a more efficient compressed-air system

Groupe Immobilier Oxford - 1250, boulevard René-Lévesque

The Oxford Properties Group reduced the electricity consumption of its building at 1250 René-Lévesque Blvd. West by over 6%.

The company updated the building's lighting system, resulting in increased lighting and reduced energy consumption.

Groupe Immobilier Oxford - Tour KPMG/Promenades Cathédrale Complex

Hydro-Québec is pleased to announce that the Oxford Properties Group’s Tour KPMG/Promenades Cathédrale complex has joined the Energy Savers’ Circle thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 8%.

To achieve these savings, the complex carried out four energy efficiency projects and implemented a series of measures, including:

- Replacing guide vanes with variable-speed drives

- Refurbishing lighting systems

- Replacing steam humidifiers with water atomizers

Parmalat Canada Inc. - Laverlochère

Parmalat Canada reduced the electricity consumption of its Laverlochère plant by 14% by:

- installing a new thermocompressor and adding an effect to the evaporator

- installing variable speed-drives on certain pieces of equipment

PF Résolu Canada Inc. – Jonquière

Abitibi-Consolidated – Kénogami Division lowered its power consumption by 5%.

After conducting an in-depth study of electricity use at its Jonquière plant, the company took steps to reduce the amount used by its motors, pumps and lighting systems.

Place Bonaventure - Montréal

Place Bonaventure carried out six projects that yielded energy savings of nearly 6% by:

- Implementing and optimizing new chillers.

- Installing new cooling towers and pumps with variable-speed drives to enhance energy management.

Place Dupuis and 888 de Maisonneuve Est

Place Dupuis and 888 De Maisonneuve Est have joined the Energy Savers' Circle thanks to a large-scale project that has helped them cut their annual electricity consumption by almost 18%.

This complex, in Montréal's Quartier Latin, comprises three office buildings and a shopping mall. After analyzing their systems and equipment, Place Dupuis and 888 De Maisonneuve Est improved their lighting, ventilation, heating and air-conditioning systems, and replaced their chillers with more efficient models.

Prodair Canada - Saint-Augustin-de-Desmaures

Prodair Canada achieved energy savings of nearly 7% in its air-separation plant in Saint-Augustin-de-Desmaures.

The company implemented four energy efficiency projects to enhance its processes and peripheral systems.

Promenades St-Bruno - Cadillac Fairview - Saint-Bruno-de-Montarville

By reducing the energy consumption considerably, Promenades St-Bruno earned a place in the Energy Savers’ Circle. Measures implemented include:

- the optimization of the indoor and outdoor lighting systems

- the installation of variable-frequency drives on the boutiques’ air-conditioning systems

Rio Tinto Aluminium Distinction

A member of the Energy Savers’ Circle since 2006 and an Elite member since 2011, Rio Tinto Aluminium rose to Distinction status thanks to efficiency measures that have led to remarkable annual electricity savings of 343 GWh, confirming its status an a energy efficiency leader.

To achieve these savings, Rio Tinto Aluminium led a number of energy efficiency projects and initiatives, including:

- electricity consumption analyses to determine opportunities to increase its efficiency

- the application of the measures identified as part of these analyses.

Sanimax Lom inc.

Hydro-Québec is pleased to welcome Sanimax Lom, specialist in ecological solutions for the agri-food industry, to the Energy Savers’ Circle. In keeping with its commitment to energy efficiency, the company has managed to reduce its annual electricity consumption by 6%.

To achieve these savings, the company carried out three energy efficiency projects and implemented a series of measures, including:

- Optimizing its compressed-air system

- Adding variable-speed drives to fans

Saputo - Bakery division - Sainte-Marie-de-Beauce

Saputo reduced the electricity consumption of its Sainte-Marie-de-Beauce plant by 16%.

The Bakery Division carried out several projects including the optimization of its ventilation and cooling systems and oven heat recovery system to heat water and fresh air.

SCA Americas – Drummondville Plant/SCA North America – Canada Inc.

Thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 9%, SCA Americas–Drummondville plant/SCA North America–Canada Inc, which manufactures personal care products, has joined the Energy Savers’ Circle.

To achieve these savings, the plant carried out six energy efficiency projects and implemented a series of measures, including:

- Optimizing use of chillers and conveyors

- Replacing light fixtures with more energy-efficient models

- Analyzing its energy consumption in order to target energy efficiency measures

SITQ - Le 1000 de la Gauchetière - Montréal

Installation of variable frequency chilled water pumps; optimization of the heating, ventilation, cooling and regulation systems. These initiatives led to energy savings of 5%.

SITQ - Place Ville Marie - Montréal

Place Ville Marie reduced its consumption by 5%.

SITQ optimized the management of its ventilation system, which is now powered only on request.

Sivaco Québec

Thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 8%, wire manufacturer Sivaco Québec has joined the Energy Savers’ Circle.

To achieve these savings, the company carried out six energy efficiency projects and implemented a series of measures, including:

- Undertaking a major replacement of the indoor lighting system

- Replacing equipment, including a compressor, with highly energy-efficient models

Société du Palais des Congrès de Montréal

The Palais des congrès cut its power consumption by 15%.

The concerted efforts of the energy committee led to the application of energy efficiency measures targeting the improvement of many systems.

- Lighting

- Heating

- Air conditioning

Société en commandite Gestion Tour de la Bourse

Hydro-Québec is very pleased to welcome Société en commandite Gestion Tour de la Bourse to the Energy Savers’ Circle. Thanks to its energy efficiency initiatives, the company reduced its annual electricity consumption by 7%.

To achieve these results, Société en commandite Gestion Tour de la Bourse implemented a series of energy efficiency measures, including:

- an analysis of its electricity consumption

- the installation of efficiency products to optimize the lighting system

- variable-speed drives (VSDs) on the ventilation systems

Société Québécoise des Infrastructures - Complexe Scientifique - Québec

The Société immobilière du Québec (SIQ) cut its electricity consumption by 6%.

SIQ optimized the Complexe scientifique's chilled water plant and heating system.

Chilled water plant

- Variable-frequency drives (VFDs) were installed to regulate systems according to actual building requirements.

Heating system

- Existing pumps were replaced by new pumps equipped with VFDs.

Société Québécoise des Infrastructures – Montréal Courthouse

La Société immobilière du Québec (Montréal courthouse) reduced its power consumption by 8%.

Courthouse ventilation and pumping systems were optimized.

- Numerous variable-frequency drives were installed.

- Several motors were replaced by more energy-efficient models.

Space for Life Distinction

Space for Life joined the Energy Savers’ Circle in 2012 as an Elite member. In 2014, the company rose to Distinction status thanks to efficiency measures that have led to remarkable annual energy savings of 40%.

To achieve these savings, the company carried out five energy efficiency projects and implemented a series of measures, including:

- Upgrading its heating system significantly

- Installing lighting fixtures based on a new concept tailored to each ecosystem

- Installing geothermal energy, heat recovery and energy transfer systems

Sun Life Assurances (Canada) Limitée – SITQ National, Sun Life Building

The Sun Life Building has joined the Energy Savers’ Circle after reducing its annual electricity consumption by 7%. The building, opened in 1918, was the first skyscraper in Montréal, and was for a long time the biggest building in the British Empire. Today it's still one of the gems of downtown Montréal real estate.

While respecting the historic character of the building, the owners, Sun Life Assurance Company of Canada and SITQ National, and real estate managers Bentall Kennedy (Canada) LP have successfully implemented a number of energy efficiency measures. These include upgrading the lighting system and replacing the thermostats controlling the heat pumps.

Tafisa Canada Inc. - Lac-Mégantic

Tafisa Canada is recognized for its commitment to energy efficiency. The Lac-Mégantic particleboard plant reduced its annual electricity consumption by 12% through a series of energy efficiency projects to:

- upgrade the lighting systems

- replace four compressors by a single, high-performance model

- install measurement equipment to better manage electricity consumption

Technocell Inc. - Drummondville

Technocell reduced its electricity consumption by 6% by implementing various measures, including:

- the installation of variable-frequency drives to better control the humidity in the dryer section

- the installation of a new lighting system

Université de Montréal

Hydro-Québec is pleased to welcome the Université de Montréal to the Energy Savers’ Circle thanks to energy efficiency initiatives that have led to annual electricity savings of 6%.

To achieve these savings, the university carried out 20 energy efficiency projects and implemented a series of measures, including:

- Undertaking several lighting-system replacement projects

- Completing a major project in the Jean-Brillant building involving many measures

- Updating ventilation systems and replaced chillers with more energy-efficient equipment

Université de Montréal - École Polytechnique

École Polytechnique reduced its overall electricity consumption by 11%.

These energy savings were generated by initiatives implemented during construction of the Lassonde buildings.

- Premium efficiency technologies and equipment are now used for heating, ventilation, cooling and lighting systems.

Université de Sherbrooke Distinction

The Université de Sherbrooke, a Hydro-Sherbrooke customer, which joined the Energy Savers’ Circle in 2009 and has been an Elite member since 2012, rose to Distinction status in 2014 thanks to efficiency measures that have led to record annual energy savings of 26%.

To achieve these savings, the university carried out more than 20 energy efficiency projects and implemented a series of measures, including:

- Optimizing its chilled-water system by introducing variable-flow

- Optimizing the chilled-water system in its heating plant

- Installing a new high-efficiency chiller in its heating plant

Université du Québec à Montréal

UQÀM reduced its consumption by 8%.

The University implemented seven energy efficiency projects.

- Heat recovery project in the new Biological Sciences pavilion

- Projects to replace the coolers and water tours in the main campus

Université du Québec à Montréal – Complexe des sciences Pierre-Dansereau

Thanks to energy efficiency initiatives that have lowered its annual electricity consumption by 8%, the Université du Québec à Montréal's Complexe des sciences Pierre-Dansereau has joined the Energy Savers' Circle.

To achieve these savings, the university carried out four energy efficiency projects and implemented a series of measures, including:

- Replacing compressors

- Installing new, more energy-efficient ventilation hoods in labs

- Improving lighting, heating and cooling in the biological sciences building

Université Laval - Québec

Université Laval cut its annual electricity consumption by more than 6% by implementing the following measures:

- Installation of efficient products and lighting control system.

- Optimization of the chilled air system including pump functioning.

Waterville TG

Waterville TG lowered its electricity consumption by 5%.

Waterville TG focused on optimizing its compressed air system.

- A number of 250-hp fixed-flow compressors were replaced by rotary screw compressors.

- Several fixed-flow compressors were replaced with a variable flow compressor.

- Several air dryers were replaced by a single, variable-capacity dryer.

- A new, more efficient oil-separating system was installed.

Recognition and visibility

Large-power customers who join the Energy Savers’ Circle win on many fronts:

- They strengthen their corporate image

- They position themselves as energy efficiency leaders in their industry.

- By saving electricity, they become more competitive—a lasting, long-term advantage.

In addition to publishing the achievements of the members of the network on its Web site, Hydro-Québec highlights the commitment of its members in various ways.

Presentation of a framed certificate

Energy Saver’s Circle Certificat

New members receive: an honorary Energy Savers’ Circle Certificate awarded during a special event.

Work of art

Elite and Distinction members receive a work of art by photographer Marie-Jeanne Musiol, who records the luminous imprints of plants.

We offer visibility

Press release and advertising

A press release and media advertisements on members’ achievements in energy efficiency are issued.

Promotional banner

A large banner that can be hung inside or outside your building.

Categories of recognition and criteria

As part of our energy efficiency programs, members of the Energy Savers' Circle carried out energy efficiency projects that resulted in significant energy savings. In order to achieve their goal, they implemented energy efficiency policies and nominated in-house energy efficiency representatives.

Membres Distinction

- Annual energy savings of:

- at least 25%, for a contract power of less than 50 MW

- at least 9% or 300 GWh, for a contract power of 50 MW or more

- Maintain of an in-house Energy Committee

- Maintain a trend chart with energy efficiency indicators

Elite Members

- Annual energy savings of:

- at least 20%, for a contract power of less than 50 MW

- at least 6% or 250 GWh, for a contract power of 50 MW or more

- Creation of an in-house Energy Committee

- Presentation of a trend chart with energy efficiency indicators

Energy Savers’ Circle Membership

- Annual energy savings of:

- at least 5% or energy savings of at least 50 GWh/year.

- Adoption of an energy efficiency policy.

- Nomination of an energy efficiency representative.

Energy Committee

The internal Energy Committee must be made up members who can adequately gage the plant or building's energy situation.

The committee must submit the minutes for three meetings which includes at least the following:

- Date of the meeting

- Names of Energy Committee members

- Objectives of the meeting or subjects discussed

Trend chart

The most recent trend chart must be submitted and include at least the following:

- Clearly identified energy efficiency indicators pertaining to electricity (for example: kWh/unit produced, kWh/t, kWh/sq. ft.)

- Results for each of the identified indicators according to established follow-up frequency (for example: weekly or monthly results)

Indicator (definition):

Series of numbers showing variation in electricity consumption based on set targets. Targets reflect the optimal functioning of a specific work process or auxiliary system.

Energy efficiency policy

The energy efficiency policy must include at least the following:

- Company’s name

- Company’s energy efficiency principles

- Signature of an authorized member of the company

Would you like to learn more about the energy savers’ circle?

Talk to your commercial officer, who will be happy to answer your questions.

Got a project planned?

Do it with advice from our experts

Business newsletter

Stay informed on our energy efficiency programs and our demand response offers.